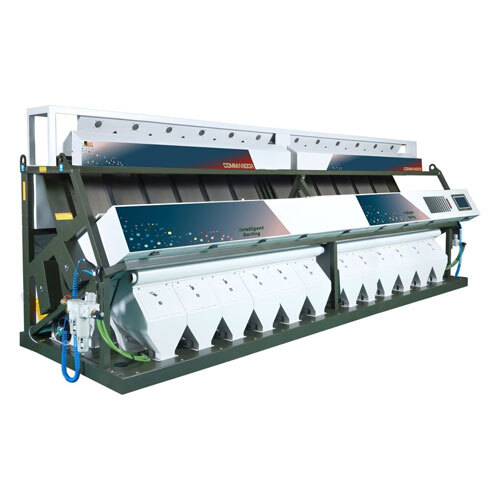

Commandor Color Sorter - 12 chute

HIGH SPEED HD CAMERA

Ultra HD imaging and analysis technology, high-speed processing, accurate identification, intelligent image processing

AI-machine learning technology

Intelligent sorting technology

Intelligent study data classification

5400x3 pixel RGB sensor

Image can be taken upto 122 million pixels per second

High level AI-machine learning technology, user friendly interface, easy operation

Multi-function, Multi-purpose, Widely used for all sorting purposes of Rice, Wheat, Dal, Pulses, Grains, Seeds, Plastics, Quartz & etc.

High end specifications ensure high stability with high sorting accuracy

Combined with color sorting, AI sorting-sort difficult impurities like micro color differences in the Product

FPGAs Based best-in-class signal processing capabilities for high bandwidth applications built on the 28nm HPL processor

HD lense for clear imaging

Ultra HD imaging and analysis technology, high-speed processing, accurate identification, intelligent image processing

AI-machine learning technology

Intelligent sorting technology

Intelligent study data classification

5400x3 pixel RGB sensor

Image can be taken upto 122 million pixels per second

High level AI-machine learning technology, user friendly interface, easy operation

Multi-function, Multi-purpose, Widely used for all sorting purposes of Rice, Wheat, Dal, Pulses, Grains, Seeds, Plastics, Quartz & etc.

High end specifications ensure high stability with high sorting accuracy

Combined with color sorting, AI sorting-sort difficult impurities like micro color differences in the Product

FPGAs Based best-in-class signal processing capabilities for high bandwidth applications built on the 28nm HPL processor

HD lense for clear imaging

HMI

MARK brand full HD colorful 10.1 touch screen

Easy to use interface

Customer friendly user interface

Linux based operating systems

Powerful communication system

MARK brand full HD colorful 10.1 touch screen

Easy to use interface

Customer friendly user interface

Linux based operating systems

Powerful communication system

FEEDER

Closed loop sensor based feeder systems self calibration

Material, even feeding system

Closed loop sensor based feeder systems self calibration

Material, even feeding system

Specifications of Commandor:-

| Chute Option Available | 1 Chute 32 Channels | 1 Chute 63 Channels | 1 Chute | 2 Chute | 3 Chute | 4 Chute | 5 Chute | 6 Chute | 7 Chute | 8 Chute | 10 Chute | 12 Chute |

| Chute Distribution (P+S+F) | 1 | 1 | 1 | 1+1 | 2+1 | 2+1+1 | 3+1+1 | 4+1+1 | 4+2+1 | 5+2+1 | 6+2+2 or 6+2+1+1 | 7+3+2 or 7+2+2+1 |

| Output (TPH) for Rice/Dal | 0.500 to 1.0 | 0.75 to 1.5 | 0.75 to 1.5 | 1 to 2 | 1.5 to 2.5 | 2 to 4 | 3 to 5 | 3.5 to 5.5 | 4 to 6 | 5 to 7 | 6 to 8 | 7 to 9 |

| No. of Camera (F&R) | 1+1 | 1+1 | 1+1 | 2+2 | 3+3 | 4+4 | 5+5 | 6+6 | 7+7 | 8+8 | 10+10 | 12+12 |

| Air Requirement @7.5cm² | 15 CFM | 28 CFM | 28 CFM | 38 CFM | 54 CFM | 72 CFM | 96 CFM | 113 CFM | 132 CFM | 150 CFM | 180 CFM | 230 CFM |

| Compressor Requirement | 5 HP Screw | 7.5 HP Screw | 7.5 HP Screw | 10 HP Screw | 15 HP Screw | 20 HP Screw | 25 HP Screw | 25 HP Screw | 30 HP Screw | 30 to 40 HP Screw | 40 HP Screw | 50 HP Screw |

| Dimension (LxWxH) Ft | 1.94 x 4.16 x 4.76 | 3 x 4.65 x 4.81 | 3.63 x 4.88 x 5.97 | 4.1 x 4.88 x 5.97 | 5.19 x 4.88 x 5.97 | 6.33 x 4.88 x 5.97 | 7.46 x 4.88 x 5.97 | 8.59 x 4.88 x 5.97 | 9.73 x 4.88 x 5.97 | 10.87 x 4.88 x 5.97 | 13.83 x 4.88 x 5.97 | 16 x 4.88 x 5.97 |

| Cabin Dimension (LxWxH) Ft | Movable type with wheel | Movable type with wheel | 7x10x8 | 8x10x8 | 9x10x8 | 10x10x8 | 12x10x8 | 13x10x8 | 14x10x8 | 16x10x8 | 18x10x8 | 20x10x8 |

Superior Sorting Technology

The Commandor Color Sorter utilizes advanced CCD full-color cameras and LED lighting to identify and separate unwanted materials with high accuracy. Its simultaneous multi-grade sorting capability ensures various grades are sorted efficiently in a single pass, streamlining the production process and maximizing productivity.

User-Friendly Operation

Equipped with a touch screen interface and microcomputer automatic control, the machine is easy to operate, monitor, and adjust. The intuitive control system allows users to quickly set parameters and achieve optimal sorting results, making it accessible for operators at any skill level.

Robust Performance and Versatility

Engineered for durability and consistent output, the Commandor Color Sorter handles a wide range of materials such as rice, pulses, grains, seeds, and plastics. Its high-frequency solenoid ejectors and smooth vibrator feeding system contribute to a controlled, low-noise, and efficient sorting environment.

FAQ's of Commandor Color Sorter - 12 chute:

Q: How does the Commandor Color Sorter achieve high sorting accuracy?

A: The Commandor Color Sorter uses full-color CCD sensor cameras and high-frequency solenoid valve ejectors, supported by LED lighting. This system detects and separates materials with color differences, ensuring a sorting accuracy of 99% or higher.Q: What types of products can be processed with this color sorter?

A: This machine is designed to sort and grade a diverse range of granular products, such as rice, grains, pulses, seeds, plastics, and other similar materials, making it versatile for various industries.Q: When is it recommended to adjust the rejection ratio settings?

A: The rejection ratio should be adjusted when changing product types, dealing with varying impurity levels, or targeting specific quality requirements. Flexible rejection settings enable optimized sorting for each production batch.Q: Where can the Commandor Color Sorter be installed?

A: It is suitable for use in processing plants, mills, and industrial facilities across India, particularly where high-volume, precise sorting is required for export, manufacturing, or supply chains.Q: What is the process for operating the Commandor Color Sorter?

A: Operators load the product into the machine's vibrant feeding system, select settings on the touch screen, and start the process. The system automatically detects and separates out impure or off-color materials, delivering accurately sorted output.Q: How does this sorter enhance operational efficiency and product quality?

A: The Commandor Color Sorter's simultaneous multi-grade sorting and high-precision ejection minimize waste and improve product quality. Efficient feeding, low rejection, and rapid processing ensure higher output per hour and superior end results.Enquiry

Copyright © 2023-24 by Promech All Rights Reserved

Design & devloped by Tradeindia.com