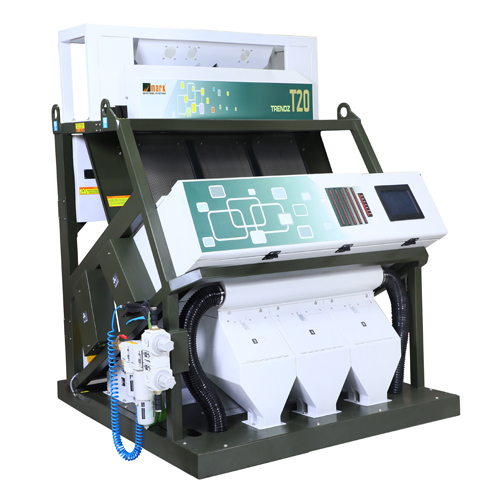

Rice Mill Color Sorting Machine

Product Features

Mark Color Sorter is designed to provide a superior performance and reliability, allowing you to avoid annoying maintenance which would effect your production. Mark Color sorter is a complete system that incorporates advanced engineering concepts.

Tri Chromatic Camera Scanner

· High Speed data acquisition and digital image

· Processing Technology Using FPGA

· Resolution -

· Highly Specialized lens for sorting purpose

· Front and back evenly aligned cameras with digital alignment technology

10'' Inch Color HMI

· Low Energy consumption led lighting

· Improves fine RGB Illumination in background

· Enhancing defects recognition systems by varying different backgrounds for different types of grains

Specifications:-

| Chute Option Available | 1 Chute | 2 Chute | 3 Chute | 4 Chute | 5 Chute | 6 Chute | 7 Chute | 8 Chute | 10 Chute | 12 Chute |

| Chute Distribution (P+S+F) | 1 | 1+1(or) 1+(40+21) | 2+1(or) 2+(40+21) | 2+1+1(or) 2+1+(40+21) | 3+1+1(or) 3+1+(40+21) | 4+1+1(or) 4+1+(40+21) | 4+2+1(or) 4+2+(40+21) | 5+2+1(or) 4+2+1 | 6+2+2(or) 6+2+1+1 | 7+3+2(or) 7+2+2+1 |

| Output (TPH) for Rice/Dall | 0.75 to 1.5 | 1 to 2 | 1.5 to 2.5 | 2 to 4 | 3 to 5 | 3.5 to 5.5 | 4 to 6 | 5 to 7 | 6 to 8 | 7 to 9 |

| No. of Camera (F&R) | 1+1 | 2+2 | 3+3 | 4+4 | 5+5 | 6+6 | 7+7 | 8+8 | 10+10 | 12+12 |

| Air Requirement @7.5kg/cm2 | 28 CFM | 38 CFM | 54 CFM | 72 CFM | 96 CFM | 113 CFM | 132 CFM | 150 CFM | 180 CFM | 230 CFM |

| Compressor Requirement | 7.5HP Screw | 10HP Screw | 15HP Screw | 20HP Screw | 25HP Screw | 25HP Screw | 30HP Screw | 30 to 40HP Screw | 40HP Screw | 50HP Screw |

| Dimension (LxWxH) Feet | 2.92x4.88x5.97 | 4.14x4.88x5.97 | 5.19x4.88x5.97 | 6.33x4.88x5.97 | 7.46x4.88x5.97 | 8.59x4.88x5.97 | 9.73x4.88x5.97 | 10.87x4.88x5.97 | 13.83x4.88x5.97 | 16x4.88x5.97 |

| Cabin Dimension (LxWxH) Feet | 7x10x8 | 8x10x8 | 9x10x8 | 10x10x8 | 12x10x8 | 13x10x8 | 14x10x8 | 16x10x8 | 18x10x8 | 20x10x8 |

Advanced Full Color CCD Image Detection

Equipped with a full color CCD image sensor and optimized LED lighting, this color sorter ensures accurate detection and classification of various rice and grain impurities. The system responds efficiently to subtle color differences, enhancing the quality of the sorted product and maximizing purity with minimum wastage.

High Efficiency Sorting and Productivity

With a sorting precision of 99.9% and a reject ratio of less than 0.2%, the machine efficiently processes 2-5 tons per hour. Its 240 channels, powerful air compressor, and robust design enable consistent high-volume sorting for industrial applications, meeting the needs of both medium and large-scale rice mills.

User-Friendly Touchscreen Control

The integrated 10-inch LED touchscreen panel provides an intuitive interface for operators, allowing easy setup, real-time monitoring, and parameter customization. It supports multiple languages, ensuring accessibility and convenience for diverse users in India and abroad.

FAQs of Rice Mill Color Sorting Machine:

Q: How does the Rice Mill Color Sorting Machine enhance rice and grain quality?

A: The machine utilizes a full color CCD image sensor combined with advanced LED illumination to detect and remove defects such as black tips, yellow grains, and foreign impurities. This high-precision sorting process ensures that only premium quality grains are selected, significantly improving the final product quality.Q: What is the operational process for this color sorting machine?

A: Rice or grains are fed into the machine, where each kernel passes in front of the full color image sensor. The system analyzes the color characteristics in real-time, and if any defect or impurity is detected, an air jet discards those grains, ensuring efficient and precise sorting.Q: When and where is this machine most beneficial for use?

A: This machine is ideally used in rice mills, grain processing plants, and export facilities where superior sorting precision and high throughput are required. It is suitable for operations in diverse climate conditions (from -10C to 45C) commonly found across India and other rice-producing regions.Q: What are the main benefits of using this rice mill color sorter for exporters and manufacturers?

A: Key advantages include improved product purity, reduced manual labor, consistent output (25 TPH), low reject ratio (<0.2%), and compliance with international quality standards. Exporters and manufacturers benefit from enhanced brand reputation and increased market competitiveness.Q: How is the machine operated and controlled by users?

A: Operators interact with the machine via a 10-inch LED touch screen display, allowing them to monitor real-time data, adjust parameters, and customize language settings. This user-friendly interface simplifies operation and facilitates efficient workflow.Q: What are the installation requirements for this sorting machine?

A: The machine requires a 220V/50Hz power supply, an air compressor with at least 7.5kW capacity, and air pressure between 0.60.8 MPa. With dimensions of 2560 x 1670 x 1650 mm and a weight of 1200 kg, it should be installed on a stable floor in an industrial facility.Enquiry

Copyright © 2023-24 by Promech All Rights Reserved

Design & devloped by Tradeindia.com