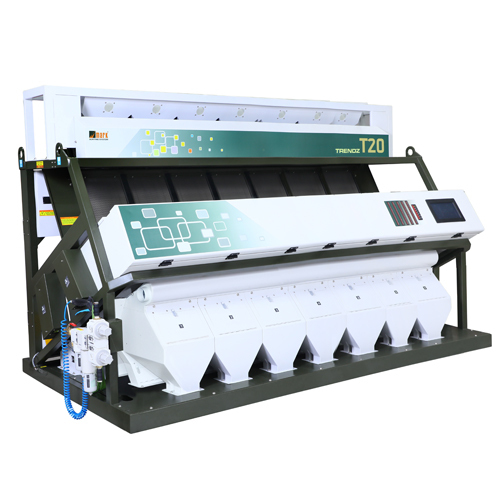

Basmati Rice Sorting Machine

Product Features

Mark Color Sorter is designed to provide a superior performance and reliability, allowing you to avoid annoying maintenance which would effect your production. Mark Color sorter is a complete system that incorporates advanced engineering concepts.

Tri Chromatic Camera Scanner

· High Speed data acquisition and digital image

· Processing Technology Using FPGA

· Resolution -

· Highly Specialized lens for sorting purpose

· Front and back evenly aligned cameras with digital alignment technology

10'' Inch Color HMI

· Low Energy consumption led lighting

· Improves fine RGB Illumination in background

· Enhancing defects recognition systems by varying different backgrounds for different types of grains

Specifications:-

| Chute Option Available | 1 Chute | 2 Chute | 3 Chute | 4 Chute | 5 Chute | 6 Chute | 7 Chute | 8 Chute | 10 Chute | 12 Chute |

| Chute Distribution (P+S+F) | 1 | 1+1(or) 1+(40+21) | 2+1(or) 2+(40+21) | 2+1+1(or) 2+1+(40+21) | 3+1+1(or) 3+1+(40+21) | 4+1+1(or) 4+1+(40+21) | 4+2+1(or) 4+2+(40+21) | 5+2+1(or) 4+2+1 | 6+2+2(or) 6+2+1+1 | 7+3+2(or) 7+2+2+1 |

| Output (TPH) for Rice/Dall | 0.75 to 1.5 | 1 to 2 | 1.5 to 2.5 | 2 to 4 | 3 to 5 | 3.5 to 5.5 | 4 to 6 | 5 to 7 | 6 to 8 | 7 to 9 |

| No. of Camera (F&R) | 1+1 | 2+2 | 3+3 | 4+4 | 5+5 | 6+6 | 7+7 | 8+8 | 10+10 | 12+12 |

| Air Requirement @7.5kg/cm2 | 28 CFM | 38 CFM | 54 CFM | 72 CFM | 96 CFM | 113 CFM | 132 CFM | 150 CFM | 180 CFM | 230 CFM |

| Compressor Requirement | 7.5HP Screw | 10HP Screw | 15HP Screw | 20HP Screw | 25HP Screw | 25HP Screw | 30HP Screw | 30 to 40HP Screw | 40HP Screw | 50HP Screw |

| Dimension (LxWxH) Feet | 2.92x4.88x5.97 | 4.14x4.88x5.97 | 5.19x4.88x5.97 | 6.33x4.88x5.97 | 7.46x4.88x5.97 | 8.59x4.88x5.97 | 9.73x4.88x5.97 | 10.87x4.88x5.97 | 13.83x4.88x5.97 | 16x4.88x5.97 |

| Cabin Dimension (LxWxH) Feet | 7x10x8 | 8x10x8 | 9x10x8 | 10x10x8 | 12x10x8 | 13x10x8 | 14x10x8 | 16x10x8 | 18x10x8 | 20x10x8 |

Cutting-edge Sorting Technology

This machine leverages intelligent image processing and AI recognition, supported by up to 138 high-resolution full-color CCD cameras, ensuring every grain is inspected with remarkable accuracy. The use of a 10-inch touch display provides intuitive controls, while the LED cold light source enhances detection quality and consistency during the sorting process.

High Efficiency and Output

With a throughput of 2 to 6 tons per hour, the machine delivers outstanding productivity for industrial operations. The reject outlet reliably separates defective grains, maintaining a 99% accuracy rate. Food-grade stainless steel contact parts safeguard rice quality and hygiene, making it perfect for Basmati rice exporters and suppliers focused on consistent excellence.

Designed for Industrial Needs

The Basmati Rice Sorting Machine is robust, weighing approximately 1200 kg and measuring 2200 mm x 1620 mm x 1900 mm. It operates with minimal noise (<75 dB) and is compatible with standard air pressures (0.6 - 0.8 MPa), fitting seamlessly into modern processing plants. Flexible voltage options and after-sales service make it a reliable choice for rice processors.

FAQs of Basmati Rice Sorting Machine:

Q: How does the Basmati Rice Sorting Machine separate defective grains from quality rice?

A: The machine uses up to 138 high-resolution full-color CCD cameras with intelligent image processing and AI recognition to identify and isolate defective grains. The reject outlet then removes these grains from the main output, ensuring only top-quality rice continues through the process.Q: What benefits does the intelligent image processing technology offer for Basmati rice sorting?

A: Intelligent image processing combined with AI recognition allows for precise detection of defects, minimizing human error and achieving 99% sorting accuracy. This results in consistently high-quality rice that meets export and manufacturing standards.Q: When should I use this machine in the rice processing workflow?

A: The sorting machine is ideally used after initial cleaning and dehusking, but before packaging, to ensure that only premium Basmati rice advances to the final stage. This optimizes the final products quality and enhances market value.Q: Where is the Basmati Rice Sorting Machine best utilized?

A: This machine is best suited for industrial Basmati rice processing plants aiming for large-scale production and high output. Its design supports exporters, manufacturers, and suppliers who demand precision, hygiene, and reliability in their sorting process.Q: What are the key steps in the rice sorting process with this machine?

A: Rice grains are fed into the machine, where each passes by high-resolution cameras. The intelligent image processing system analyzes each grain, and if defects are detected, the grain is directed to the reject outlet using controlled air jets supported by the required air compressor.Q: Is the machine easy to operate and maintain?

A: Yes, the 10-inch touch screen display provides an intuitive interface for easy operation. The food-grade stainless steel parts are not only durable but also easy to clean and maintain, and after-sales service ensures continued reliable performance.Enquiry

Copyright © 2023-24 by Promech All Rights Reserved

Design & devloped by Tradeindia.com