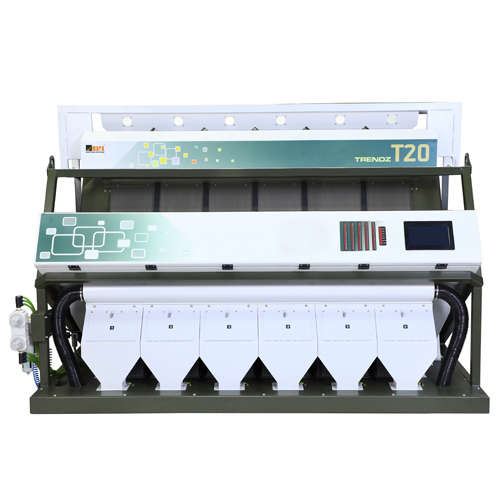

T20 Color Sorter Machine

Product Features

Mark Color Sorter is designed to provide a superior performance and reliability, allowing you to avoid annoying maintenance which would effect your production. Mark Color sorter is a complete system that incorporates advanced engineering concepts.

Tri Chromatic Camera Scanner

· High Speed data acquisition and digital image

· Processing Technology Using FPGA

· Resolution -

· Highly Specialized lens for sorting purpose

· Front and back evenly aligned cameras with digital alignment technology

10'' Inch Color HMI

· Low Energy consumption led lighting

· Improves fine RGB Illumination in background

· Enhancing defects recognition systems by varying different backgrounds for different types of grains

Specifications:-

| Chute Option Available | 1 Chute | 2 Chute | 3 Chute | 4 Chute | 5 Chute | 6 Chute | 7 Chute | 8 Chute | 10 Chute | 12 Chute |

| Chute Distribution (P+S+F) | 1 | 1+1(or) 1+(40+21) | 2+1(or) 2+(40+21) | 2+1+1(or) 2+1+(40+21) | 3+1+1(or) 3+1+(40+21) | 4+1+1(or) 4+1+(40+21) | 4+2+1(or) 4+2+(40+21) | 5+2+1(or) 4+2+1 | 6+2+2(or) 6+2+1+1 | 7+3+2(or) 7+2+2+1 |

| Output (TPH) for Rice/Dall | 0.75 to 1.5 | 1 to 2 | 1.5 to 2.5 | 2 to 4 | 3 to 5 | 3.5 to 5.5 | 4 to 6 | 5 to 7 | 6 to 8 | 7 to 9 |

| No. of Camera (F&R) | 1+1 | 2+2 | 3+3 | 4+4 | 5+5 | 6+6 | 7+7 | 8+8 | 10+10 | 12+12 |

| Air Requirement @7.5kg/cm2 | 28 CFM | 38 CFM | 54 CFM | 72 CFM | 96 CFM | 113 CFM | 132 CFM | 150 CFM | 180 CFM | 230 CFM |

| Compressor Requirement | 7.5HP Screw | 10HP Screw | 15HP Screw | 20HP Screw | 25HP Screw | 25HP Screw | 30HP Screw | 30 to 40HP Screw | 40HP Screw | 50HP Screw |

| Dimension (LxWxH) Feet | 2.92x4.88x5.97 | 4.14x4.88x5.97 | 5.19x4.88x5.97 | 6.33x4.88x5.97 | 7.46x4.88x5.97 | 8.59x4.88x5.97 | 9.73x4.88x5.97 | 10.87x4.88x5.97 | 13.83x4.88x5.97 | 16x4.88x5.97 |

| Cabin Dimension (LxWxH) Feet | 7x10x8 | 8x10x8 | 9x10x8 | 10x10x8 | 12x10x8 | 13x10x8 | 14x10x8 | 16x10x8 | 18x10x8 | 20x10x8 |

Advanced Sorting Technology

Leveraging CCD cameras paired with LED illumination, the T20 Color Sorter Machine detects and separates materials with remarkable accuracy. The touch screen interface streamlines control, while high-speed ejectors enhance sorting speed, resulting in a cleaner end product. This technologically advanced system ensures reliable operation even in demanding industrial settings.

Robust Construction and Reliable Performance

The machines stainless steel body facilitates durability and ease of maintenance. Operating quietly at 75 dB and within a broad temperature range of -10C to 40C, it suits a variety of environments. Its automatic digital controls support hassle-free performance, making it an ideal choice for businesses managing high-capacity sorting tasks.

Wide Industrial Application

Designed for sorting seeds, grains, pulses, rice, plastics, and minerals, the T20 Color Sorter meets the needs of exporters, manufacturers, and suppliers. With a capacity of 23 tons per hour and a low reject ratio, its an efficient solution for bulk material processing, ensuring consistent output quality across diverse industries in India.

FAQs of T20 Color Sorter Machine:

Q: How does the T20 Color Sorter Machine achieve such high sorting accuracy?

A: The T20 uses advanced CCD cameras and LED lighting to capture nuanced color differences, allowing its software to isolate and eject defective or mismatched materials with an impressive 99.99% accuracy rate.Q: What materials can be processed using this color sorter machine?

A: The machine is designed to sort a wide range of materials, including seeds, grains, pulses, rice, plastics, and minerals, making it a versatile solution for varied industrial applications.Q: When is the machine most efficiently operated?

A: Optimal efficiency is achieved when the T20 Color Sorter operates within its specified temperature range of -10C to 40C and at the recommended air pressure of 0.60.8 MPa, ensuring peak sorting performance and minimal reject ratios.Q: Where can the T20 Color Sorter Machine be installed for best results?

A: It is recommended to install the machine in a stable, clean industrial environment with access to a 220V/50Hz power supply and an external air compressor to facilitate uninterrupted operation.Q: What is the sorting process of the T20 Color Sorter Machine?

A: Input material passes through 160 sorting channels, where CCD cameras and LED lighting identify unwanted colors or defects. High-speed ejectors then quickly remove the defective items, ensuring only finished sorted material is output.Q: How is the machine controlled and operated?

A: The T20 is managed via a touch screen display and features automatic digital controls, making operation user-friendly and enabling precise adjustments for optimized sorting results.Q: What are the main benefits of using the T20 Color Sorter Machine?

A: Businesses benefit from enhanced sorting precision, increased throughput up to 3 tons per hour, low reject rates, reduced manual intervention, and superior output qualityall contributing to higher productivity and improved margins.Enquiry

Copyright © 2023-24 by Promech All Rights Reserved

Design & devloped by Tradeindia.com