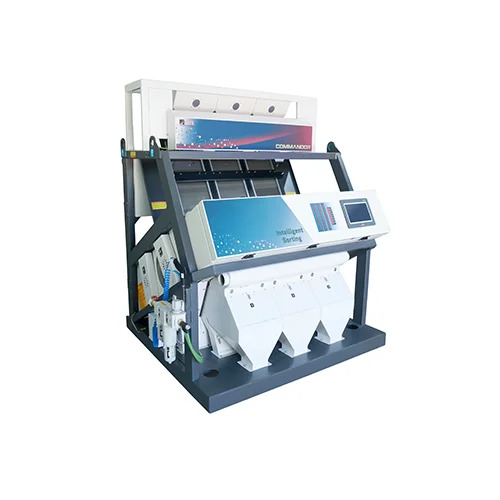

pulses color sorter machine in coimbatore

HIGH SPEED HD CAMERA

Ultra HD imaging and analysis technology, high-speed processing, accurate identification, intelligent image processing

AI-machine learning technology

Intelligent sorting technology

Intelligent study data classification

5400x3 pixel RGB sensor

Image can be taken upto 122 million pixels per second

High level AI-machine learning technology, user friendly interface, easy operation

Multi-function, Multi-purpose, Widely used for all sorting purposes of Rice, Wheat, Dal, Pulses, Grains, Seeds, Plastics, Quartz & etc.

High end specifications ensure high stability with high sorting accuracy

Combined with color sorting, AI sorting-sort difficult impurities like micro color differences in the Product

FPGAs Based best-in-class signal processing capabilities for high bandwidth applications built on the 28nm HPL processor

HD lense for clear imaging

Ultra HD imaging and analysis technology, high-speed processing, accurate identification, intelligent image processing

AI-machine learning technology

Intelligent sorting technology

Intelligent study data classification

5400x3 pixel RGB sensor

Image can be taken upto 122 million pixels per second

High level AI-machine learning technology, user friendly interface, easy operation

Multi-function, Multi-purpose, Widely used for all sorting purposes of Rice, Wheat, Dal, Pulses, Grains, Seeds, Plastics, Quartz & etc.

High end specifications ensure high stability with high sorting accuracy

Combined with color sorting, AI sorting-sort difficult impurities like micro color differences in the Product

FPGAs Based best-in-class signal processing capabilities for high bandwidth applications built on the 28nm HPL processor

HD lense for clear imaging

HMI

MARK brand full HD colorful 10.1 touch screen

Easy to use interface

Customer friendly user interface

Linux based operating systems

Powerful communication system

MARK brand full HD colorful 10.1 touch screen

Easy to use interface

Customer friendly user interface

Linux based operating systems

Powerful communication system

FEEDER

Closed loop sensor based feeder systems self calibration

Material, even feeding system

Closed loop sensor based feeder systems self calibration

Material, even feeding system

Specifications of Commandor:-

| Chute Option Available | 1 Chute 32 Channels | 1 Chute 63 Channels | 1 Chute | 2 Chute | 3 Chute | 4 Chute | 5 Chute | 6 Chute | 7 Chute | 8 Chute | 10 Chute | 12 Chute |

| Chute Distribution (P+S+F) | 1 | 1 | 1 | 1+1 | 2+1 | 2+1+1 | 3+1+1 | 4+1+1 | 4+2+1 | 5+2+1 | 6+2+2 or 6+2+1+1 | 7+3+2 or 7+2+2+1 |

| Output (TPH) for Rice/Dal | 0.500 to 1.0 | 0.75 to 1.5 | 0.75 to 1.5 | 1 to 2 | 1.5 to 2.5 | 2 to 4 | 3 to 5 | 3.5 to 5.5 | 4 to 6 | 5 to 7 | 6 to 8 | 7 to 9 |

| No. of Camera (F&R) | 1+1 | 1+1 | 1+1 | 2+2 | 3+3 | 4+4 | 5+5 | 6+6 | 7+7 | 8+8 | 10+10 | 12+12 |

| Air Requirement @7.5cm² | 15 CFM | 28 CFM | 28 CFM | 38 CFM | 54 CFM | 72 CFM | 96 CFM | 113 CFM | 132 CFM | 150 CFM | 180 CFM | 230 CFM |

| Compressor Requirement | 5 HP Screw | 7.5 HP Screw | 7.5 HP Screw | 10 HP Screw | 15 HP Screw | 20 HP Screw | 25 HP Screw | 25 HP Screw | 30 HP Screw | 30 to 40 HP Screw | 40 HP Screw | 50 HP Screw |

| Dimension (LxWxH) Ft | 1.94 x 4.16 x 4.76 | 3 x 4.65 x 4.81 | 3.63 x 4.88 x 5.97 | 4.1 x 4.88 x 5.97 | 5.19 x 4.88 x 5.97 | 6.33 x 4.88 x 5.97 | 7.46 x 4.88 x 5.97 | 8.59 x 4.88 x 5.97 | 9.73 x 4.88 x 5.97 | 10.87 x 4.88 x 5.97 | 13.83 x 4.88 x 5.97 | 16 x 4.88 x 5.97 |

| Cabin Dimension (LxWxH) Ft | Movable type with wheel | Movable type with wheel | 7x10x8 | 8x10x8 | 9x10x8 | 10x10x8 | 12x10x8 | 13x10x8 | 14x10x8 | 16x10x8 | 18x10x8 | 20x10x8 |

Advanced AI-Driven Sorting Technology

Experience superior pulse sorting precision with AI-enhanced RGB color sorting and CCD sensors. This technology distinguishes minute flaws, ensuring each batch of lentils, beans, or peas meets strict quality standards. The 6-channel system and high-speed air ejectors further contribute to efficient defect rejection, promoting premium-grade pulse output.

Robust Design and User-Friendly Operation

Constructed from food-grade stainless steel, this machine is built for industrial use and durability. The fully automatic system is managed via a touch screen HMI that supports remote firmware upgrades, streamlining operation and maintenance. Its low noise profile and reliable LED lighting offer a comfortable working environment for extended operational hours.

Comprehensive Support and Data Management

On-site installation and training in India ensure hassle-free setup for exporters, manufacturers, and suppliers. Inbuilt data recording allows for process optimization and traceability, while remote software updates keep the system up-to-date with the latest features for sustained performance.

FAQs of pulses color sorter machine in coimbatore:

Q: How does the Pulses Color Sorter Machine achieve 99% sorting accuracy?

A: The machine employs AI-enhanced RGB technology and CCD high-resolution sensors to meticulously identify color and structural defects in pulses. Advanced algorithms, paired with rapid air ejection and multi-channel processing, ensure precise removal of even the smallest contaminants, resulting in consistently clean and accurately sorted output.Q: What pulses can be sorted using this machine and at what capacity?

A: It efficiently sorts a range of pulses, including lentils, peas, and beans. Able to handle between 500 kg/hr and 3 tons/hr, the machine is suitable for industrial-scale production for exporters, manufacturers, and suppliers across India.Q: When is on-site installation and training provided for this machine?

A: On-site installation and training services are arranged upon purchase and delivery. Expert technicians will set up the machine, calibrate it, and instruct your team in operational procedures and regular maintenance for optimal results.Q: Where is this pulses color sorter manufactured and supported?

A: The machine is designed and manufactured in Coimbatore, India. Comprehensive service support, including on-site installation and remote diagnostics, is available to customers nationwide, covering exporters, suppliers, and manufacturers.Q: What is the process of sorting pulses using the machine?

A: Pulses are fed into the machine, where CCD cameras and AI algorithms scan for defects. Using 6 channels and powerful air compressors, faulty grains are discarded through a stainless steel reject hopper, while clean pulses proceed to the output section. All sorting data is stored for review and quality assurance.Q: Can the sorting parameters and machine data be accessed and updated remotely?

A: Yes, the machine features inbuilt data recording for sorting parameters and enables remote firmware upgrades. Users can manage sorting profiles and receive the latest software updates without interrupting workflow.Q: What are the main benefits of using this color sorter machine in industrial pulse processing?

A: Key advantages include exceptional sorting accuracy, quick defect rejection, robust construction, fully automatic operation, low noise levels, hygienic food-grade materials, user-friendly controls, and comprehensive support. It helps ensure high purity, efficient throughput, and long-term reliability for pulse processing businesses.Enquiry

Copyright © 2023-24 by Promech All Rights Reserved

Design & devloped by Tradeindia.com