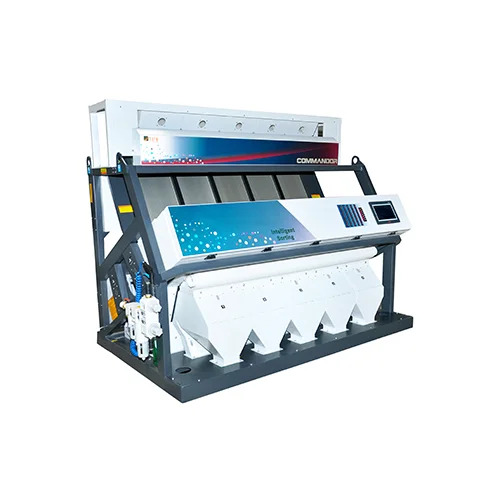

Dall Color Sorter

HIGH SPEED HD CAMERA

Ultra HD imaging and analysis technology, high-speed processing, accurate identification, intelligent image processing

AI-machine learning technology

Intelligent sorting technology

Intelligent study data classification

5400x3 pixel RGB sensor

Image can be taken upto 122 million pixels per second

High level AI-machine learning technology, user friendly interface, easy operation

Multi-function, Multi-purpose, Widely used for all sorting purposes of Rice, Wheat, Dal, Pulses, Grains, Seeds, Plastics, Quartz & etc.

High end specifications ensure high stability with high sorting accuracy

Combined with color sorting, AI sorting-sort difficult impurities like micro color differences in the Product

FPGAs Based best-in-class signal processing capabilities for high bandwidth applications built on the 28nm HPL processor

HD lense for clear imaging

Ultra HD imaging and analysis technology, high-speed processing, accurate identification, intelligent image processing

AI-machine learning technology

Intelligent sorting technology

Intelligent study data classification

5400x3 pixel RGB sensor

Image can be taken upto 122 million pixels per second

High level AI-machine learning technology, user friendly interface, easy operation

Multi-function, Multi-purpose, Widely used for all sorting purposes of Rice, Wheat, Dal, Pulses, Grains, Seeds, Plastics, Quartz & etc.

High end specifications ensure high stability with high sorting accuracy

Combined with color sorting, AI sorting-sort difficult impurities like micro color differences in the Product

FPGAs Based best-in-class signal processing capabilities for high bandwidth applications built on the 28nm HPL processor

HD lense for clear imaging

HMI

MARK brand full HD colorful 10.1 touch screen

Easy to use interface

Customer friendly user interface

Linux based operating systems

Powerful communication system

MARK brand full HD colorful 10.1 touch screen

Easy to use interface

Customer friendly user interface

Linux based operating systems

Powerful communication system

FEEDER

Closed loop sensor based feeder systems self calibration

Material, even feeding system

Closed loop sensor based feeder systems self calibration

Material, even feeding system

Specifications of Commandor:-

| Chute Option Available | 1 Chute 32 Channels | 1 Chute 63 Channels | 1 Chute | 2 Chute | 3 Chute | 4 Chute | 5 Chute | 6 Chute | 7 Chute | 8 Chute | 10 Chute | 12 Chute |

| Chute Distribution (P+S+F) | 1 | 1 | 1 | 1+1 | 2+1 | 2+1+1 | 3+1+1 | 4+1+1 | 4+2+1 | 5+2+1 | 6+2+2 or 6+2+1+1 | 7+3+2 or 7+2+2+1 |

| Output (TPH) for Rice/Dal | 0.500 to 1.0 | 0.75 to 1.5 | 0.75 to 1.5 | 1 to 2 | 1.5 to 2.5 | 2 to 4 | 3 to 5 | 3.5 to 5.5 | 4 to 6 | 5 to 7 | 6 to 8 | 7 to 9 |

| No. of Camera (F&R) | 1+1 | 1+1 | 1+1 | 2+2 | 3+3 | 4+4 | 5+5 | 6+6 | 7+7 | 8+8 | 10+10 | 12+12 |

| Air Requirement @7.5cm² | 15 CFM | 28 CFM | 28 CFM | 38 CFM | 54 CFM | 72 CFM | 96 CFM | 113 CFM | 132 CFM | 150 CFM | 180 CFM | 230 CFM |

| Compressor Requirement | 5 HP Screw | 7.5 HP Screw | 7.5 HP Screw | 10 HP Screw | 15 HP Screw | 20 HP Screw | 25 HP Screw | 25 HP Screw | 30 HP Screw | 30 to 40 HP Screw | 40 HP Screw | 50 HP Screw |

| Dimension (LxWxH) Ft | 1.94 x 4.16 x 4.76 | 3 x 4.65 x 4.81 | 3.63 x 4.88 x 5.97 | 4.1 x 4.88 x 5.97 | 5.19 x 4.88 x 5.97 | 6.33 x 4.88 x 5.97 | 7.46 x 4.88 x 5.97 | 8.59 x 4.88 x 5.97 | 9.73 x 4.88 x 5.97 | 10.87 x 4.88 x 5.97 | 13.83 x 4.88 x 5.97 | 16 x 4.88 x 5.97 |

| Cabin Dimension (LxWxH) Ft | Movable type with wheel | Movable type with wheel | 7x10x8 | 8x10x8 | 9x10x8 | 10x10x8 | 12x10x8 | 13x10x8 | 14x10x8 | 16x10x8 | 18x10x8 | 20x10x8 |

Advanced Sorting Technology

The Dall Color Sorter utilizes CCD sensors paired with an RGB full color camera, ensuring precise detection and removal of discolored or unwanted materials. High-efficiency LED lamps enhance the clarity and accuracy of the sorting process, making it ideal for a wide range of dall and pulses.

Robust Design for Commercial Use

Built with a durable stainless steel frame, the machine is tailored for industrial sorting operations. Its touch screen PLC control system streamlines setup and adjustment, enabling efficient sorting in both single and multi-stage modes, depending on specific material requirements.

Efficient, Reliable Operation

The sorter operates quietly at less than 70 dB and is compatible with standard commercial voltages (220V/380V, 50/60 Hz). Its long-life ejector valves, rated for over 5 billion cycles, and recommended air compressor ensure continuous operation with minimal downtime and high throughput.

FAQ's of Dall Color Sorter:

Q: How does the Dall Color Sorter achieve high sorting accuracy?

A: The Dall Color Sorter uses CCD sensors and an RGB full color camera to identify and separate impurities with remarkable precision. Coupled with high-efficiency LED lighting and intelligent software, the machine reaches a sorting accuracy of 99.9%, ensuring premium quality for sorted dals and pulses.Q: What types of materials can be processed with the Dall Color Sorter?

A: This color sorter is designed to handle various types of dall, lentils, pulses, and grains. Its adaptable channels and material size settings enable efficient sorting of most commercial grain products used in the food industry.Q: When is single-stage or multi-stage sorting recommended?

A: Single-stage sorting is effective for basic cleaning of materials, whereas multi-stage sorting is beneficial for achieving higher purity or handling complex grain types. Users can select the appropriate stage based on their sorting requirements and product quality goals.Q: Where can the Dall Color Sorter be installed and used?

A: The machine is ideal for commercial grain processing facilities, pulse mills, and lentil sorting plants. Its robust design and operating temperature range make it suitable for use across diverse industrial settings in India and abroad.Q: What is the process behind sorted output and selectable separation?

A: Material enters the sorter, passes through channels where the CCD sensor detects unwanted color variations, and high-speed ejector valves remove impurities. The sorted output can be adjusted by operators using the touch screen PLC, ensuring tailored results for each batch.Q: How does using a recommended air compressor benefit machine performance?

A: A 7.5 HP air compressor provides optimal air pressure (0.6-0.8 MPa) for the ejector valves, guaranteeing fast and reliable impurity removal even at high throughput rates. This ensures consistent sorting quality and machine longevity.Q: What are the usage and benefits of the Dall Color Sorter in commercial applications?

A: With a capacity of 2-4 tons per hour and a rejection ratio below 0.2%, the Dall Color Sorter greatly reduces labor, increases sorting speed, and improves output quality. Its stainless steel body and long-life components offer cost-effective, robust solutions for exporters, manufacturers, and suppliers in the grain industry.Enquiry

Copyright © 2023-24 by Promech All Rights Reserved

Design & devloped by Tradeindia.com