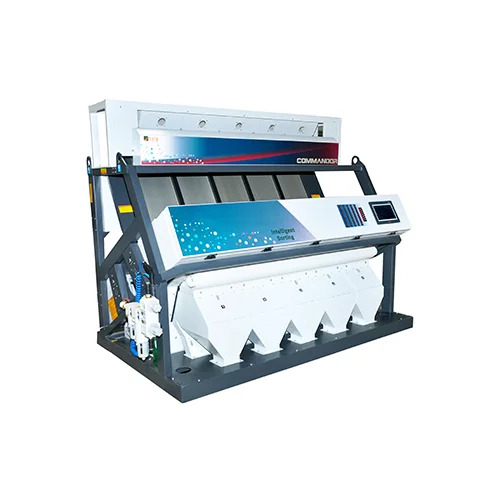

Raisin Sorting Machine

HIGH SPEED HD CAMERA

Ultra HD imaging and analysis technology, high-speed processing, accurate identification, intelligent image processing

AI-machine learning technology

Intelligent sorting technology

Intelligent study data classification

5400x3 pixel RGB sensor

Image can be taken upto 122 million pixels per second

High level AI-machine learning technology, user friendly interface, easy operation

Multi-function, Multi-purpose, Widely used for all sorting purposes of Rice, Wheat, Dal, Pulses, Grains, Seeds, Plastics, Quartz & etc.

High end specifications ensure high stability with high sorting accuracy

Combined with color sorting, AI sorting-sort difficult impurities like micro color differences in the Product

FPGAs Based best-in-class signal processing capabilities for high bandwidth applications built on the 28nm HPL processor

HD lense for clear imaging

Ultra HD imaging and analysis technology, high-speed processing, accurate identification, intelligent image processing

AI-machine learning technology

Intelligent sorting technology

Intelligent study data classification

5400x3 pixel RGB sensor

Image can be taken upto 122 million pixels per second

High level AI-machine learning technology, user friendly interface, easy operation

Multi-function, Multi-purpose, Widely used for all sorting purposes of Rice, Wheat, Dal, Pulses, Grains, Seeds, Plastics, Quartz & etc.

High end specifications ensure high stability with high sorting accuracy

Combined with color sorting, AI sorting-sort difficult impurities like micro color differences in the Product

FPGAs Based best-in-class signal processing capabilities for high bandwidth applications built on the 28nm HPL processor

HD lense for clear imaging

HMI

MARK brand full HD colorful 10.1 touch screen

Easy to use interface

Customer friendly user interface

Linux based operating systems

Powerful communication system

MARK brand full HD colorful 10.1 touch screen

Easy to use interface

Customer friendly user interface

Linux based operating systems

Powerful communication system

FEEDER

Closed loop sensor based feeder systems self calibration

Material, even feeding system

Closed loop sensor based feeder systems self calibration

Material, even feeding system

Specifications of Commandor:-

| Chute Option Available | 1 Chute 32 Channels | 1 Chute 63 Channels | 1 Chute | 2 Chute | 3 Chute | 4 Chute | 5 Chute | 6 Chute | 7 Chute | 8 Chute | 10 Chute | 12 Chute |

| Chute Distribution (P+S+F) | 1 | 1 | 1 | 1+1 | 2+1 | 2+1+1 | 3+1+1 | 4+1+1 | 4+2+1 | 5+2+1 | 6+2+2 or 6+2+1+1 | 7+3+2 or 7+2+2+1 |

| Output (TPH) for Rice/Dal | 0.500 to 1.0 | 0.75 to 1.5 | 0.75 to 1.5 | 1 to 2 | 1.5 to 2.5 | 2 to 4 | 3 to 5 | 3.5 to 5.5 | 4 to 6 | 5 to 7 | 6 to 8 | 7 to 9 |

| No. of Camera (F&R) | 1+1 | 1+1 | 1+1 | 2+2 | 3+3 | 4+4 | 5+5 | 6+6 | 7+7 | 8+8 | 10+10 | 12+12 |

| Air Requirement @7.5cm² | 15 CFM | 28 CFM | 28 CFM | 38 CFM | 54 CFM | 72 CFM | 96 CFM | 113 CFM | 132 CFM | 150 CFM | 180 CFM | 230 CFM |

| Compressor Requirement | 5 HP Screw | 7.5 HP Screw | 7.5 HP Screw | 10 HP Screw | 15 HP Screw | 20 HP Screw | 25 HP Screw | 25 HP Screw | 30 HP Screw | 30 to 40 HP Screw | 40 HP Screw | 50 HP Screw |

| Dimension (LxWxH) Ft | 1.94 x 4.16 x 4.76 | 3 x 4.65 x 4.81 | 3.63 x 4.88 x 5.97 | 4.1 x 4.88 x 5.97 | 5.19 x 4.88 x 5.97 | 6.33 x 4.88 x 5.97 | 7.46 x 4.88 x 5.97 | 8.59 x 4.88 x 5.97 | 9.73 x 4.88 x 5.97 | 10.87 x 4.88 x 5.97 | 13.83 x 4.88 x 5.97 | 16 x 4.88 x 5.97 |

| Cabin Dimension (LxWxH) Ft | Movable type with wheel | Movable type with wheel | 7x10x8 | 8x10x8 | 9x10x8 | 10x10x8 | 12x10x8 | 13x10x8 | 14x10x8 | 16x10x8 | 18x10x8 | 20x10x8 |

Advanced Sorting Technology

This machine integrates CCD cameras and AI algorithms, enabling extremely high sorting accuracy for raisins. The true-color LED lighting allows the detection system to distinguish subtle color variations, ensuring only the finest produce passes through.

Robust Construction and Design

Constructed from stainless steel 304, the sorting machine offers durability and hygiene suitable for food processing environments. Vibration feeding trays and a six-channel system optimize the flow and sorting rate, supporting industrial-scale operations.

User-Friendly Operation

A digital touch screen control interface simplifies machine operation and monitoring. The digital display provides real-time data on sorting performance, making it easy for operators to track and adjust settings as needed.

FAQs of Raisin Sorting Machine:

Q: How does the raisin sorting machine achieve such high sorting accuracy?

A: The machine combines CCD camera technology with AI to analyze each raisin as it passes through. Advanced algorithms detect subtle differences in color, size, and shape, achieving up to 99% sorting accuracy for defects and foreign materials.Q: What is the process for operating this raisin sorting machine?

A: Operation begins with loading raisins onto the vibration feeding tray, which evenly distributes them across six channels. As raisins move through, LED lighting and CCD cameras scan each item, and AI software makes sorting decisions. Sorted output is then separated by color grade, defects, and foreign material.Q: When should the air compressor be connected during setup?

A: The air compressor should be connected prior to starting the machine, as it supplies the necessary 0.60.8 MPa air pressure for the sorting mechanisms. Ensure the compressor is stable and capable before initial operation.Q: Where can this sorting machine be used effectively?

A: This machine is designed for use in raisin processing plants and food industry facilities requiring precise sorting. Its robust build and high throughput make it well-suited for both domestic and international industrial environments.Q: What are the main benefits of using this machine for raisin processing?

A: Key benefits include highly efficient and accurate sorting, reduced reject rates (<0.2%), improved product quality, and minimized labor costs. The stainless steel build ensures hygiene and long-term durability.Q: How does the touch screen control interface enhance usability?

A: The touch screen allows operators to easily adjust sorting parameters, view real-time data, and monitor machine status. This simplifies setup, operation, and maintenance, minimizing operator training time.Enquiry

Copyright © 2023-24 by Promech All Rights Reserved

Design & devloped by Tradeindia.com