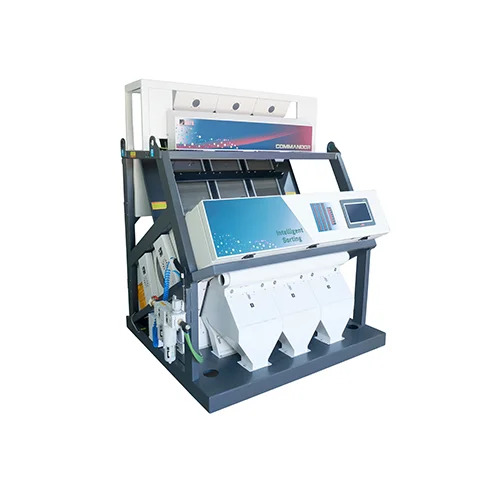

Peanut Color Sorter

HIGH SPEED HD CAMERA

Ultra HD imaging and analysis technology, high-speed processing, accurate identification, intelligent image processing

AI-machine learning technology

Intelligent sorting technology

Intelligent study data classification

5400x3 pixel RGB sensor

Image can be taken upto 122 million pixels per second

High level AI-machine learning technology, user friendly interface, easy operation

Multi-function, Multi-purpose, Widely used for all sorting purposes of Rice, Wheat, Dal, Pulses, Grains, Seeds, Plastics, Quartz & etc.

High end specifications ensure high stability with high sorting accuracy

Combined with color sorting, AI sorting-sort difficult impurities like micro color differences in the Product

FPGAs Based best-in-class signal processing capabilities for high bandwidth applications built on the 28nm HPL processor

HD lense for clear imaging

Ultra HD imaging and analysis technology, high-speed processing, accurate identification, intelligent image processing

AI-machine learning technology

Intelligent sorting technology

Intelligent study data classification

5400x3 pixel RGB sensor

Image can be taken upto 122 million pixels per second

High level AI-machine learning technology, user friendly interface, easy operation

Multi-function, Multi-purpose, Widely used for all sorting purposes of Rice, Wheat, Dal, Pulses, Grains, Seeds, Plastics, Quartz & etc.

High end specifications ensure high stability with high sorting accuracy

Combined with color sorting, AI sorting-sort difficult impurities like micro color differences in the Product

FPGAs Based best-in-class signal processing capabilities for high bandwidth applications built on the 28nm HPL processor

HD lense for clear imaging

HMI

MARK brand full HD colorful 10.1 touch screen

Easy to use interface

Customer friendly user interface

Linux based operating systems

Powerful communication system

MARK brand full HD colorful 10.1 touch screen

Easy to use interface

Customer friendly user interface

Linux based operating systems

Powerful communication system

FEEDER

Closed loop sensor based feeder systems self calibration

Material, even feeding system

Closed loop sensor based feeder systems self calibration

Material, even feeding system

Specifications of Commandor:-

| Chute Option Available | 1 Chute 32 Channels | 1 Chute 63 Channels | 1 Chute | 2 Chute | 3 Chute | 4 Chute | 5 Chute | 6 Chute | 7 Chute | 8 Chute | 10 Chute | 12 Chute |

| Chute Distribution (P+S+F) | 1 | 1 | 1 | 1+1 | 2+1 | 2+1+1 | 3+1+1 | 4+1+1 | 4+2+1 | 5+2+1 | 6+2+2 or 6+2+1+1 | 7+3+2 or 7+2+2+1 |

| Output (TPH) for Rice/Dal | 0.500 to 1.0 | 0.75 to 1.5 | 0.75 to 1.5 | 1 to 2 | 1.5 to 2.5 | 2 to 4 | 3 to 5 | 3.5 to 5.5 | 4 to 6 | 5 to 7 | 6 to 8 | 7 to 9 |

| No. of Camera (F&R) | 1+1 | 1+1 | 1+1 | 2+2 | 3+3 | 4+4 | 5+5 | 6+6 | 7+7 | 8+8 | 10+10 | 12+12 |

| Air Requirement @7.5cm² | 15 CFM | 28 CFM | 28 CFM | 38 CFM | 54 CFM | 72 CFM | 96 CFM | 113 CFM | 132 CFM | 150 CFM | 180 CFM | 230 CFM |

| Compressor Requirement | 5 HP Screw | 7.5 HP Screw | 7.5 HP Screw | 10 HP Screw | 15 HP Screw | 20 HP Screw | 25 HP Screw | 25 HP Screw | 30 HP Screw | 30 to 40 HP Screw | 40 HP Screw | 50 HP Screw |

| Dimension (LxWxH) Ft | 1.94 x 4.16 x 4.76 | 3 x 4.65 x 4.81 | 3.63 x 4.88 x 5.97 | 4.1 x 4.88 x 5.97 | 5.19 x 4.88 x 5.97 | 6.33 x 4.88 x 5.97 | 7.46 x 4.88 x 5.97 | 8.59 x 4.88 x 5.97 | 9.73 x 4.88 x 5.97 | 10.87 x 4.88 x 5.97 | 13.83 x 4.88 x 5.97 | 16 x 4.88 x 5.97 |

| Cabin Dimension (LxWxH) Ft | Movable type with wheel | Movable type with wheel | 7x10x8 | 8x10x8 | 9x10x8 | 10x10x8 | 12x10x8 | 13x10x8 | 14x10x8 | 16x10x8 | 18x10x8 | 20x10x8 |

Unmatched Sorting Precision

This peanut color sorter delivers outstanding sorting accuracy, thanks to its 5400-pixel industrial camera and CCD-based optical system. The machines 0.01 mm detection sensitivity ensures only top-quality peanuts pass through, significantly boosting product value and minimizing losses. Its microprocessor-controlled operation and advanced ejector valves remove defects with a ratio of over 10:1, offering superior consistency and reliability in every batch.

Efficient Industrial Operation

Engineered for industrial-scale food processing, the machines automatic mode and vibration feed streamline the sorting workflow, allowing continuous, high-volume throughput of 10002000 kg/hr. With a sturdy build weighing 600 kg and a compact footprint, it integrates seamlessly into modern production lines catering to exporters, manufacturers, and suppliers seeking higher output and efficiency.

User-Friendly Technology

A responsive touch screen interface makes operation intuitive, supporting quick adjustments and real-time monitoring. The LED lighting source enhances visual clarity for accurate color sorting in varying lighting conditions, while the system operates quietly at 75 dB(A). Maintenance becomes straightforward with a service life exceeding 10 billion valve cycles, ensuring minimal downtime.

FAQs of Peanut Color Sorter:

Q: How does the Peanut Color Sorter achieve such high sorting accuracy?

A: The sorter uses a CCD camera-based optical system with 5400-pixel industrial cameras and LED lighting to capture and analyze peanuts in real time. Its 0.01 mm detection sensitivity enables it to identify and reject defective peanuts with greater than 99% accuracy.Q: What is the process for operating the machine, and is it fully automatic?

A: The Peanut Color Sorter operates in automatic mode. Peanuts are fed through a vibration and chute feed system, detected by high-resolution cameras under LED illumination, and sorted based on color analysis. Ejector valves automatically remove defects, all controlled via a touch screen interface for ease of use.Q: When is it suitable to use this sorter in industrial settings?

A: This sorter is ideal for continuous industrial applications in food processing, peanut cleaning, and export operations. It works efficiently within an operating temperature range of -5C to 40C, allowing reliable year-round performance.Q: Where should the Peanut Color Sorter be installed for optimal results?

A: Install the machine in a dedicated industrial processing area with adequate ventilation and space for its dimensions (1560 x 1630 x 2000 mm). Ensure theres access to a compatible power supply (220V/380V, 50Hz) and provision for an air compressor (0.60.8 MPa) needed for operation.Q: What are the main benefits of using this Peanut Color Sorter?

A: Key benefits include exceptional color sorting accuracy, rapid processing speeds (up to 2000 kg/hr), low noise emission, minimal defects, and a long service life. Its automation and intuitive controls help reduce labor costs and improve product quality, making it highly advantageous for exporters and manufacturers.Q: How should the feeding system and air compressor be set up?

A: For best performance, use the vibration feed and chute system to maintain a consistent flow of peanuts. An external air compressor (not included) with 0.60.8 MPa pressure is necessary to power the ejector valves efficiently during defect removal.Enquiry

Copyright © 2023-24 by Promech All Rights Reserved

Design & devloped by Tradeindia.com