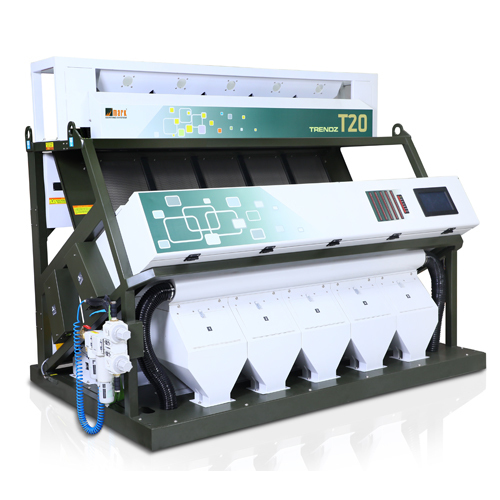

Mark Color Sorter Machine - T20

Product Features

Mark Color Sorter is designed to provide a superior performance and reliability, allowing you to avoid annoying maintenance which would effect your production. Mark Color sorter is a complete system that incorporates advanced engineering concepts.

Tri Chromatic Camera Scanner

· High Speed data acquisition and digital image

· Processing Technology Using FPGA

· Resolution -

· Highly Specialized lens for sorting purpose

· Front and back evenly aligned cameras with digital alignment technology

10'' Inch Color HMI

· Low Energy consumption led lighting

· Improves fine RGB Illumination in background

· Enhancing defects recognition systems by varying different backgrounds for different types of grains

Specifications:-

| Chute Option Available | 1 Chute | 2 Chute | 3 Chute | 4 Chute | 5 Chute | 6 Chute | 7 Chute | 8 Chute | 10 Chute | 12 Chute |

| Chute Distribution (P+S+F) | 1 | 1+1(or) 1+(40+21) | 2+1(or) 2+(40+21) | 2+1+1(or) 2+1+(40+21) | 3+1+1(or) 3+1+(40+21) | 4+1+1(or) 4+1+(40+21) | 4+2+1(or) 4+2+(40+21) | 5+2+1(or) 4+2+1 | 6+2+2(or) 6+2+1+1 | 7+3+2(or) 7+2+2+1 |

| Output (TPH) for Rice/Dall | 0.75 to 1.5 | 1 to 2 | 1.5 to 2.5 | 2 to 4 | 3 to 5 | 3.5 to 5.5 | 4 to 6 | 5 to 7 | 6 to 8 | 7 to 9 |

| No. of Camera (F&R) | 1+1 | 2+2 | 3+3 | 4+4 | 5+5 | 6+6 | 7+7 | 8+8 | 10+10 | 12+12 |

| Air Requirement @7.5kg/cm2 | 28 CFM | 38 CFM | 54 CFM | 72 CFM | 96 CFM | 113 CFM | 132 CFM | 150 CFM | 180 CFM | 230 CFM |

| Compressor Requirement | 7.5HP Screw | 10HP Screw | 15HP Screw | 20HP Screw | 25HP Screw | 25HP Screw | 30HP Screw | 30 to 40HP Screw | 40HP Screw | 50HP Screw |

| Dimension (LxWxH) Feet | 2.92x4.88x5.97 | 4.14x4.88x5.97 | 5.19x4.88x5.97 | 6.33x4.88x5.97 | 7.46x4.88x5.97 | 8.59x4.88x5.97 | 9.73x4.88x5.97 | 10.87x4.88x5.97 | 13.83x4.88x5.97 | 16x4.88x5.97 |

| Cabin Dimension (LxWxH) Feet | 7x10x8 | 8x10x8 | 9x10x8 | 10x10x8 | 12x10x8 | 13x10x8 | 14x10x8 | 16x10x8 | 18x10x8 | 20x10x8 |

Advanced Sorting Precision

The T20 Color Sorter utilizes sophisticated RGB full color sorting technology and a CCD sensor camera to achieve a remarkable 99.99% accuracy. This ensures only the highest quality products make it through, significantly reducing waste and re-sorting needs.

User-Friendly & Efficient Operation

Equipped with a responsive touch screen interface and an automatic operation mode, the T20 simplifies sorting processes. The vibrator feeder system and powerful LED lighting guarantee consistent feeding and optimal color detection even in demanding food processing environments.

Robust Build & High Throughput

Constructed with high-grade stainless steel, the T20 offers exceptional durability for continuous industrial use. With a capacity to process 2-4 tons per hour, this machine is ideal for exporters, manufacturers, and suppliers aiming for high output while maintaining superior sorting standards.

FAQ's of Mark Color Sorter Machine - T20:

Q: How does the Mark Color Sorter Machine - T20 achieve such high sorting accuracy?

A: The T20 employs a state-of-the-art CCD sensor camera combined with RGB full color sorting technology, enabling it to detect and separate unwanted materials with 99.99% precision. Its 256 channels and LED lighting further enhance the detection of subtle color differences.Q: What materials or products can the T20 Color Sorter be used for?

A: This machine is designed for automatic color sorting of rice, grains, seeds, and various products in the food processing industry. Its versatile technology caters to a broad range of applications where color sorting is vital.Q: When is it recommended to use the T20 Color Sorter in the processing workflow?

A: The T20 is best utilized after the initial cleaning and grading stages. Integrating it at this point ensures that defective, discolored, or unwanted foreign particles are sorted out before final packaging or further processing.Q: Where can the Mark Color Sorter Machine - T20 be installed?

A: The T20 is suitable for installation in food processing plants, milling facilities, grain storage sites, and manufacturing units. Its manageable dimensions (1600 x 1510 x 1960 mm) and robust construction make it adaptable for various industrial environments.Q: What is the process behind the T20's automatic color sorting function?

A: Raw materials are fed into the machine through the vibrator feeder, where the CCD sensor camera analyzes each item under LED illumination. The sorting system automatically identifies and ejects defective items using compressed air, ensuring only premium-quality output passes through.Q: How does using the T20 Color Sorter benefit manufacturers and exporters?

A: Manufacturers and exporters gain from reduced reject rates, higher product consistency, and increased throughput. The machine's precision and high sorting capacity help meet international quality standards, improving market competitiveness and profitability.Enquiry

Copyright © 2023-24 by Promech All Rights Reserved

Design & devloped by Tradeindia.com