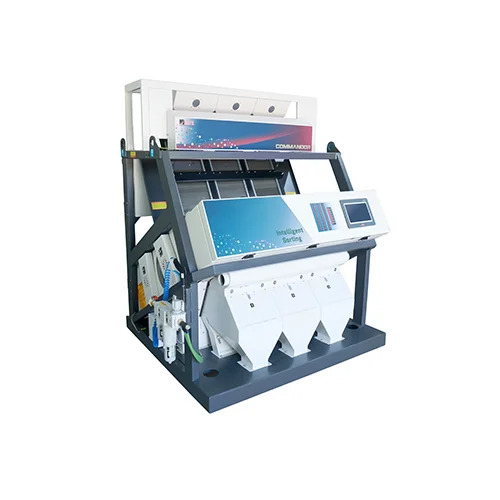

Spices Color Sorting Machine

HIGH SPEED HD CAMERA

Ultra HD imaging and analysis technology, high-speed processing, accurate identification, intelligent image processing

AI-machine learning technology

Intelligent sorting technology

Intelligent study data classification

5400x3 pixel RGB sensor

Image can be taken upto 122 million pixels per second

High level AI-machine learning technology, user friendly interface, easy operation

Multi-function, Multi-purpose, Widely used for all sorting purposes of Rice, Wheat, Dal, Pulses, Grains, Seeds, Plastics, Quartz & etc.

High end specifications ensure high stability with high sorting accuracy

Combined with color sorting, AI sorting-sort difficult impurities like micro color differences in the Product

FPGAs Based best-in-class signal processing capabilities for high bandwidth applications built on the 28nm HPL processor

HD lense for clear imaging

HMI

MARK brand full HD colorful 10.1 touch screen

Easy to use interface

Customer friendly user interface

Linux based operating systems

Powerful communication system

FEEDER

Closed loop sensor based feeder systems self calibration

Material, even feeding system

Specifications of Commandor:-

Chute Option Available 1 Chute 32 Channels 1 Chute 63 Channels 1 Chute 2 Chute 3 Chute 4 Chute 5 Chute 6 Chute 7 Chute 8 Chute 10 Chute 12 Chute Chute Distribution (P+S+F) 1 1 1 1+1 2+1 2+1+1 3+1+1 4+1+1 4+2+1 5+2+1 6+2+2

or

6+2+1+17+3+2

or

7+2+2+1Output (TPH) for Rice/Dal 0.500 to 1.0 0.75 to 1.5 0.75 to 1.5 1 to 2 1.5 to 2.5 2 to 4 3 to 5 3.5 to 5.5 4 to 6 5 to 7 6 to 8 7 to 9 No. of Camera (F&R) 1+1 1+1 1+1 2+2 3+3 4+4 5+5 6+6 7+7 8+8 10+10 12+12 Air Requirement @7.5cm² 15 CFM 28 CFM 28 CFM 38 CFM 54 CFM 72 CFM 96 CFM 113 CFM 132 CFM 150 CFM 180 CFM 230 CFM Compressor Requirement 5 HP Screw 7.5 HP Screw 7.5 HP Screw 10 HP Screw 15 HP Screw 20 HP Screw 25 HP Screw 25 HP Screw 30 HP Screw 30 to 40 HP Screw 40 HP Screw 50 HP Screw Dimension (LxWxH) Ft 1.94 x 4.16 x 4.76 3 x 4.65 x 4.81 3.63 x 4.88 x 5.97 4.1 x 4.88 x 5.97 5.19 x 4.88 x 5.97 6.33 x 4.88 x 5.97 7.46 x 4.88 x 5.97 8.59 x 4.88 x 5.97 9.73 x 4.88 x 5.97 10.87 x 4.88 x 5.97 13.83 x 4.88 x 5.97 16 x 4.88 x 5.97 Cabin Dimension (LxWxH) Ft Movable type

with wheelMovable type

with wheel7x10x8 8x10x8 9x10x8 10x10x8 12x10x8 13x10x8 14x10x8 16x10x8 18x10x8 20x10x8

Advanced Sorting Technology for Spices

Equipped with high-end CCD sensors and fiber optics, this machine identifies and separates even the subtle shades in spices at remarkable accuracy. The precise color differentiation ensures only high-quality batches pass through, reducing human error and improving operational efficiency in spice processing plants.

Efficient and User-Friendly Operation

A 10-inch touchscreen interface allows for seamless control, customized settings, and real-time monitoring. The automated dust cleaning system keeps the sorting compartment free from debris, ensuring consistent performance and minimal maintenance downtime. Experience hassle-free operation tailored for frequent, high-volume use.

Durable and Reliable Industrial Solution

Built with a stainless steel body and long-life LED lighting (50,000 hours), this machine is engineered for longevity in demanding environments. Its low noise level, continuous output capability, and support for recommended 7.5 HP air compressors make it an ideal investment for large-scale industrial applications in the food and spice sectors.

FAQ's of Spices Color Sorting Machine:

Q: How does the Spices Color Sorting Machine achieve high accuracy in sorting?

A: The machine utilizes advanced CCD image sensors combined with high-resolution fiber optics to detect and distinguish even minute color differences in spices. This technology, alongside precise ejection mechanisms, enables a sorting accuracy of 99.9% and a reject ratio of 0.05%.Q: What types of spices can this color sorting machine handle?

A: This machine is suitable for sorting a wide variety of spices, including chili, turmeric, cumin, coriander, and more. Its high sensitivity and adaptable sorting parameters make it ideal for both whole and ground spices in various sizes and shapes.Q: When should the automatic dust removal system be activated?

A: The automatic dust removal system operates periodically during machine use to prevent dust accumulation, ensuring that sensors and optical components remain clean. This function helps maintain sorting accuracy and reduces the need for frequent manual cleaning.Q: Where is the Spices Color Sorting Machine typically installed?

A: It is commonly installed in food processing and spice milling facilities, particularly in sorting lines where separating impurities or discolored particles from bulk spices is essential for quality control. The machine's continuous output makes it well-suited for large-scale industrial environments.Q: What is the process flow for sorting spices using this machine?

A: Spices are fed into the hopper, pass through the high-resolution fiber optic and CCD color detection system, and are automatically separated by air jets into accepted and rejected categories based on color. The sorted output is continuously conveyed for further packaging or processing.Q: How can users benefit from employing this color sorting machine?

A: Users benefit from improved product quality, higher operational efficiency, and reduced labor costs. The machine ensures a consistent, high-precision sort, minimizes wastage, and supports compliance with industry standards for spice grading and export.Enquiry

Copyright © 2023-24 by Promech All Rights Reserved

Design & devloped by Tradeindia.com